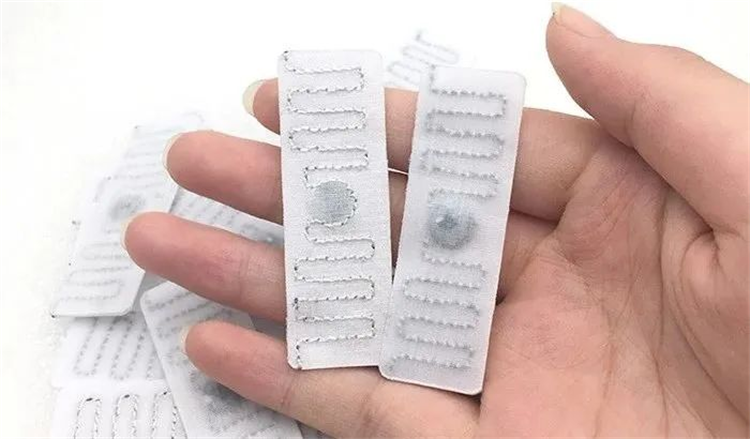

RFID washable label is the application of RFID radio frequency identification technology. By sewing a strip-shaped electronic washing label on each piece of linen, this RFID laundry tag has a unique global identification code and can be used repeatedly. It can be used throughout the linen, In washing management, read in batches through RFID readers, and automatically record the use status and washing times of linen. It makes the handover of washing tasks simple and transparent, and reduces business disputes. At the same time, by tracking the number of washings, it can estimate the service life of the current linen for the user and provide forecast data for the procurement plan.

1. Application of RFID laundry tags in hospital clothing management

In September 2018, Jewish General Hospital deployed an RFID solution to track medical staff and the uniforms they wear, from delivery to laundry and then reuse in clean closets. According to the hospital, this is a popular and effective solution.

Traditionally, employees would go to the racks where the uniforms are stored and pick up their uniforms themselves. After their shifts, they take their uniforms home to launder or put them in hampers to be cleaned and sanitized in the laundry room. Who takes what and who owns what is done with little oversight. The uniform problem is exacerbated by hospitals limiting the size of their uniform needs when there is a risk of shortages. This has resulted in hospitals needing to purchase uniforms in bulk to ensure they never run out of uniforms needed for surgery. Plus, the racking areas where uniforms are stored are often cluttered, causing employees to rummage through other items while they look for the clothes they need; uniforms can also be found in closets and offices at times. Both conditions increase the risk of infection.

In addition, they also installed an RFID smart collection cabinet in the locker room. When the cabinet door is closed, the interrogator takes another inventory and the software determines which items have been taken and links these items to the user ID accessing the cabinet. The software can set a specific number of clothes for each user to receive.

So if a user doesn’t return enough dirty clothes, that person won’t have access to the clean uniform inventory to pick up new clothes. Built-in reader and antenna for managing returned items. The user places the returned garment in the locker, and the reader triggers the read only after the door is closed and the magnets engage. The cabinet door is completely shielded, thus eliminating the risk of misinterpreting the reading of the label on the outside of the cabinet. An LED light on the cabinet lights up to notify the user that it has been returned correctly. At the same time, the software will delete such information from personal information.

2. Advantages of RFID laundry tags in hospital clothing management system

Batch inventory can be realized without unpacking, effectively controlling hospital infection

According to the requirements of the Hospital Infection Management Department for ward management, quilt covers, bed sheets, pillowcases, patient gowns and other linen used by patients should be sealed and packed in dirty laundry trucks and transported to the washing department for disposal. The reality is that in order to reduce disputes caused by the loss of quilts, the personnel receiving and dispatching quilts need to check with the personnel in the department when they are sending and receiving quilts in the department. This working mode is not only inefficient, but also has secondary problems. Risk of infection and cross-infection between departments. After the implementation of the clothing chip management system, the unpacking and inventory link is omitted when the clothing and clothing are handed over in each ward, and the hand-held mobile phone is used to quickly scan the packaged dirty clothes in batches and print out the linen list, which can effectively avoid secondary pollution and Environmental pollution, reduce the incidence of nosocomial infection, and improve the intangible benefits of the hospital.

Full life cycle control of clothes, greatly reducing the loss rate

Clothes are circulated among the using departments, sending and receiving departments, and washing departments. It is difficult to track whereabouts, the phenomenon of loss is serious, and disputes between handover personnel often occur. The traditional sending and receiving process needs to manually count the clothes one by one many times, which has the problems of high classification error rate and low efficiency. The RFID clothing chip can reliably track the washing times and the turnover process of the clothing, and can carry out evidence-based responsibility identification for the lost clothing, clarify the lost link, reduce the clothing loss rate, save the clothing cost, and can effectively reduce management costs. Improve employee satisfaction.

Save handover time, optimize the sending and receiving process, and reduce labor costs

The reader/writer of the RFID terminal system can quickly identify the chip information of the clothing, the handheld machine can scan 100 pieces in 10 seconds, and the tunnel machine can scan 200 pieces in 5 seconds, which greatly improves the efficiency of sending and receiving, and saves the supervision and inventory time of the medical staff in the department. And reduce the occupation of hospital elevator resources. In the case of limited resources, by optimizing the staffing of the sending and receiving department and the allocation of elevator resources, more resources can be used to serve the clinic, and the quality of logistics services can be continuously improved and improved.

Reduce the backlog of department clothes and reduce procurement costs

By setting the number of washes and service life of quilts through the system platform, it is possible to track the historical washing and use records of current quilts throughout the process, estimate their service life, provide scientific decision-making basis for the procurement plan of quilts, solve the backlog of quilts in the warehouse and the shortage of models, and reduce the cost of quilts. The procurement department has a safe stock of stock, saving storage space and capital occupation. According to statistics, the use of RFID washable label chip management system can reduce textile purchases by 5%, reduce uncirculated inventory by 4%, and reduce non-theft loss of textiles by 3%.

Multi-dimensional data statistical reports provide management decision-making basis

The bedding management system platform can accurately monitor the hospital bedding data, obtain the bedding needs of each department in real time, and generate multi-dimensional statistical reports by analyzing the bedding records of the whole hospital, including department usage, size statistics, and washing production statistics , Turnover statistics, workload statistics, inventory statistics, scrap loss statistics, cost statistics, etc., provide scientific basis for hospital logistics management decision-making.

Post time: Jun-07-2023