UHF RFID Chips for Uniforms, Garments and Linens

UHF RFID Chips for Uniforms, Garments and Linens

The Washable UHF RFID Laundry Tag is designed for industrial and medical laundry applications, ensuring reliable tracking and identification of textiles through rigorous washing processes. This tag can endure more than 200 industrial wash cycles while maintaining optimal performance under extreme conditions.

Key Features:

- Durability:

- Designed to withstand over 200 industrial wash cycles.

- Capable of enduring up to 60 Bar atmospheric pressure, making it suitable for high-pressure washing environments.

- Performance Testing:

- 100% memory write test completed to ensure data integrity.

- Material and design have undergone rigorous reliability testing.

- Inspected for 100% RF consistency using advanced Finland Tagformace equipment.

- Design:

- Soft and flexible textile material ensures comfort and adaptability in various applications.

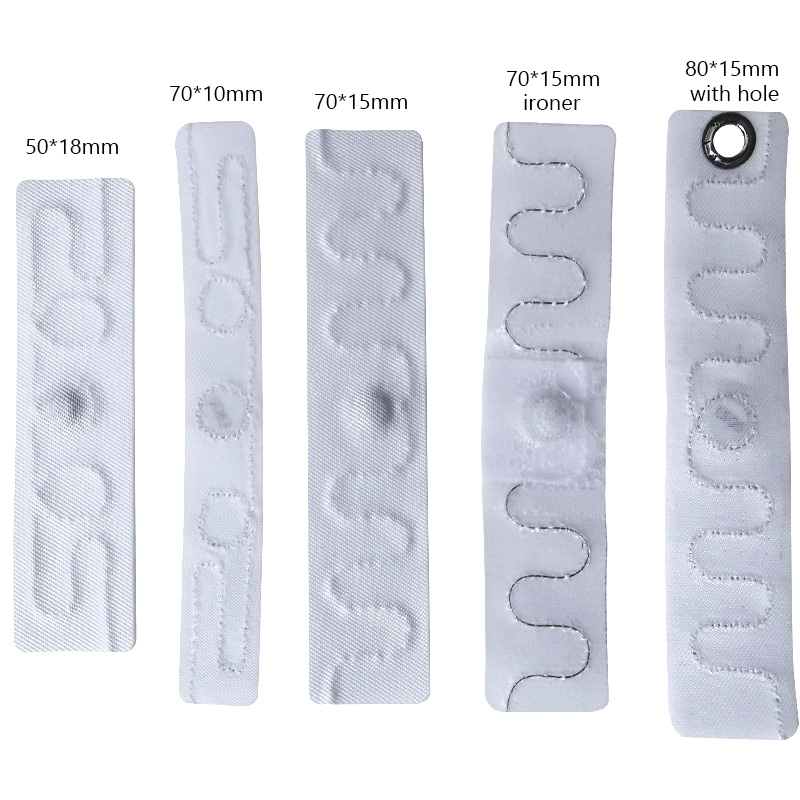

- Dimensions: 15 mm x 70 mm x 1.5 mm, featuring the NXP U CODE 9 chip for enhanced performance.

- Surface Material:

- Made from high-quality textile materials that are compatible with industrial laundry processes.

Applications:

- Ideal for use in hospitals, hotels, and industrial laundries where tracking and managing textile assets is crucial.

Conclusion:

The Washable UHF RFID Laundry Tag combines advanced technology with robust design to provide a reliable solution for textile identification and tracking in demanding environments. Its ability to withstand extreme washing conditions makes it an essential tool for industries requiring high standards of cleanliness and efficiency.

Specification:

| Working Frequency | 902-928MHz or 865~866MHz |

| Feature | R/W |

| Size | 70mm x 15mm x 1.5mm or customized |

| Chip Type | UHF Code 7M, or UHF Code 8 |

| Storage | EPC 96bits User 32bits |

| Warranty | 2years or 200 times laundry |

| Working Temperature | -25~ +110 ° C |

| Storage Temperature | -40 ~ +85 ° C |

| High Temperature Resistance | 1) Washing: 90 degrees, 15 minutes, 200 times 2) Converter pre-drying: 180 degrees, 30 minutes,200 times 3) Ironing: 180 degrees, 10 seconds, 200 times 4) High temperature sterilization: 135 degrees,20 minutesStorage humidity 5% ~ 95% |

| Storage humidity | 5% ~ 95% |

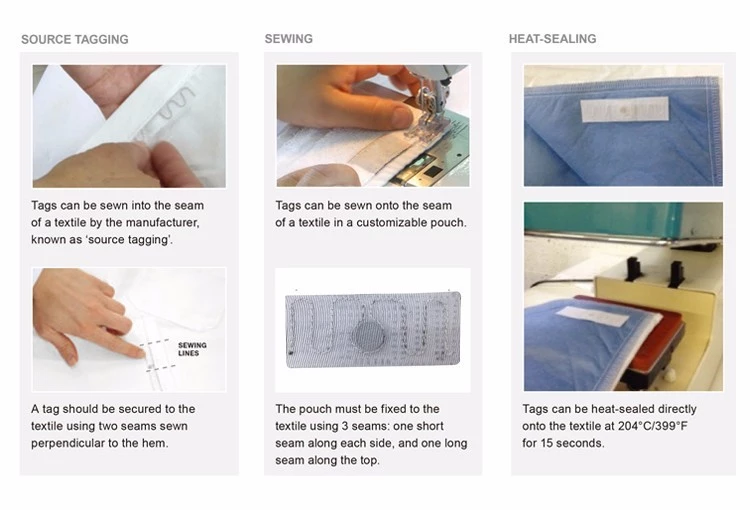

| Installation method | 10-Laundry7015:Sew in the hem or installin the woven jacket 10-Laundry7015H: 215 ℃ @ 15 seconds and 4 bars (0.4MPa) pressure Force hot stamping, or suture installation (please contact the original factory before installation See the detailed installation method), or install in the woven jacket |

| Product weight | 0.7 g / piece |

| Packaging | carton packing |

| Surface | color white |

| Pressure | Withstands 60 bars |

| Chemically resistant | resistant to all chemicals used in normal industrial washing processes |

| Reading distance | Fixed: more than 5.5 meters (ERP = 2W) Handheld: more than 2 meters (using ATID AT880 handheld) |

| Polarization mode | Linear polarization |

Improve Operational Efficiencies

Control the flow of your assets anywhere/anytime, perform faster and more accurate counts, improve on-time delivery performance, automate garment dispensers and manage wearer details.

Reduce Costs

Monitor Quality & Laundry Services

Product shows

Advantages of Washable Laundry Tag:

1. Accelerate the turnover of cloth and reduce the amount of inventory, reduce the loss.

2 . Quantify the washing process and monitor the number of washing, improve customer satisfaction

3, quantify the quality of cloth, more targeted selection of cloth producers

4, simplify the handover, inventory process, improve staff efficiency